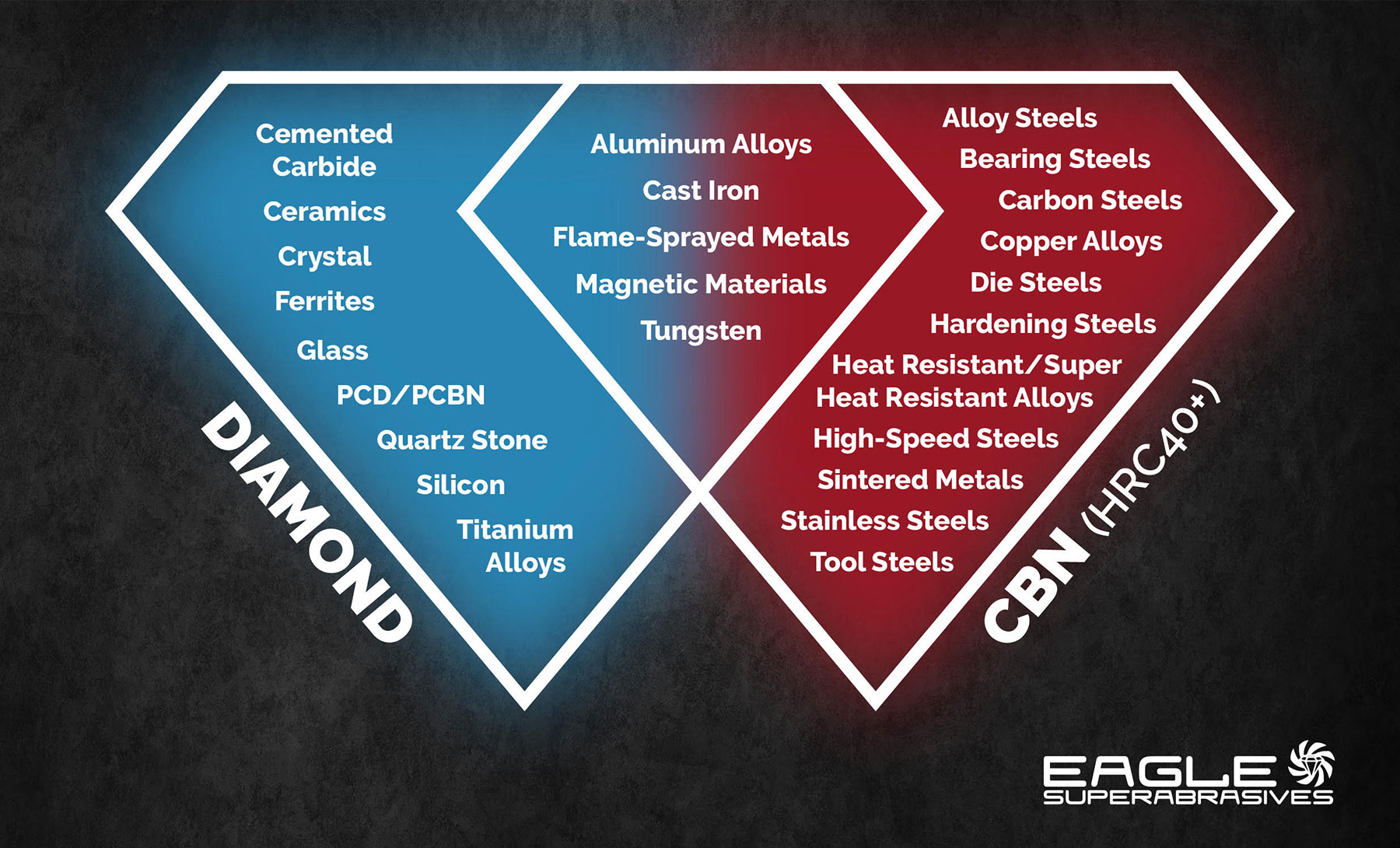

Selecting the correct abrasive, whether diamond or CBN, is crucial for achieving optimal grinding results. Diamond abrasives excel in precision grinding of hard materials like carbides, ceramics, and glass, offering superior surface finish and tight tolerances. CBN abrasives are tailored for tough-to-machine materials such as hardened steels and superalloys, providing efficient stock removal and dimensional stability even under high-speed grinding conditions.

The Wheel Builder

The bond is the material/matrix used to keep the abrasive grit on the wheel,

- Resin Bond: Soft, offering a smooth finish, suitable for grinding carbide and ceramics.

- Electroplated Bond: Single layer of diamonds attached with nickel, ideal for precision and high material removal.

- Poly Bond: Polymer-based, flexible, used for polishing and fine grinding.

- Vitrified Bond: Hard, brittle, and heat-resistant, used for precision grinding.

- Metal Bond: Strong and durable, used for heavy-duty grinding of hard materials.

- Hybrid Bond: Combines resin and metal, offering a balance of strength and smooth finish for various applications.

If you are unsure, lets us know and we can assist.

If you are unsure exactly what you need, whether it is the bond, abrasive or even the size of the wheel, check the box and it will take you directly to the Submission form and we will help you define what you need.

Understanding the grinding wheel’s application is crucial for creating a wheel that meets expectations. We have many bonds and core materials available and knowing the application allows us to quote a wheel that better suits the actual wheel that will be needed. Customizing the wheel ensures optimal performance, durability, and cost-effectiveness.

Standard grinding wheel shapes like 11V9 and 14F1R are defined by the FEPA classification system, which standardizes wheel geometries for consistency across the industry. For instance, 11V9 is a dish-shaped wheel for precision grinding, while 14F1R is a flat-profiled wheel with a continuous rim for slicing or profiling. Choose the closest shape to your needs.