Glass & Ceramic

Ceramics & Glass Solutions

From cutting pipes and tubes to cutting ceramics and grinding glass, Eagle Superabrasives has your operation covered. We manufacture wheels for pencil edging glass and general glass grinding for all industries. We offer advanced grinding solutions tailor-made for any kind of industrial application. Our high precision diamond grinding wheels work longer, cut faster, and are more durable than our competitors – and we have the data to prove it!

We offer industry-leading solutions like our Opti-tech wheels for glass grinding applications, offering improved edge quality, specialized bond options, and customized solutions to fit your application. If you are looking for enhanced edge finish, quieter grinding, faster production speed and reduced wheel dressing, give Eagle a call.

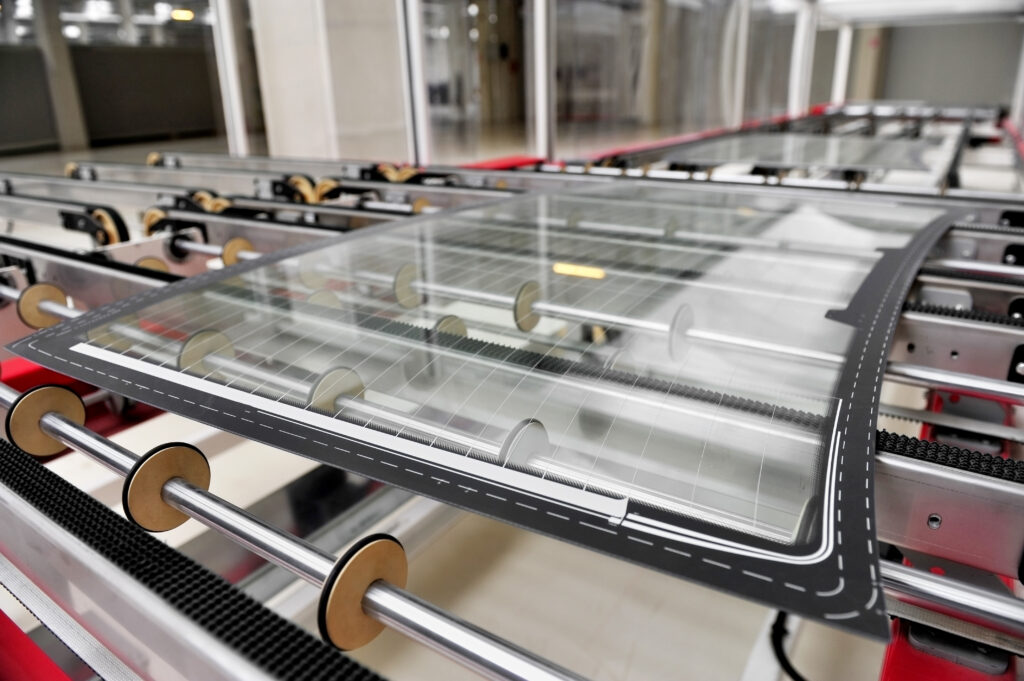

OptiTEC Wheels

For Beveling Glass

Eagle Superabrasives’ OptiTEC grinding wheel line offers metal and resin bonds specialized to suit your application. If you are looking for enhanced edge finish, quieter grinding, faster production speed and reduced wheel dressing, look no further than this wheel for your glass grinding operations.

Our OptiTEC wheels eliminate chipping issues by using our superior blend of diamond particles to maintain the sharpest cutting edge in any operation. A sharper diamond is critical when grinding glass. If the diamond is too blocky or rounds over too quickly due to wear, the wheel will start to chip the glass and ruin your parts. Eagle is ready to assist in your operations by providing this unique solution.

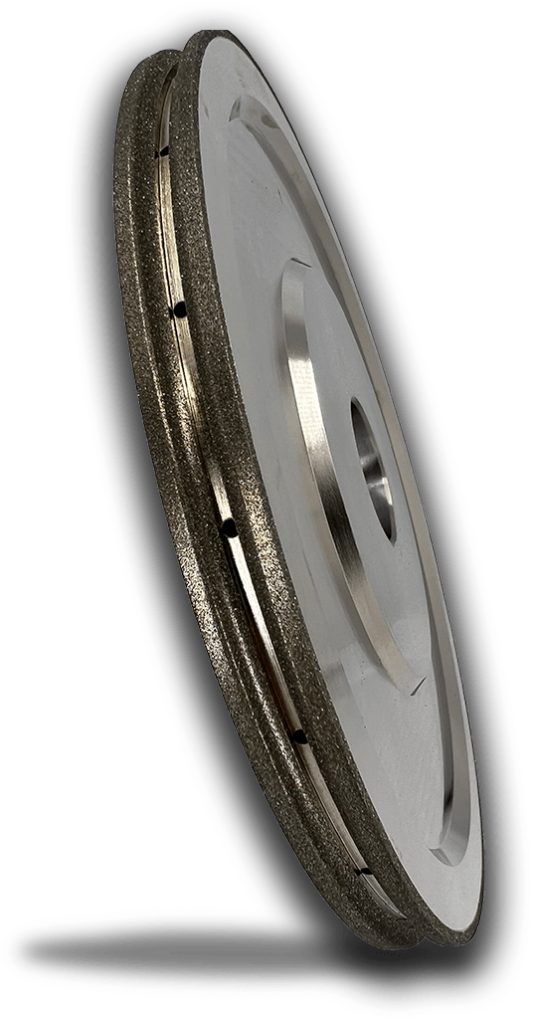

MultiTEC Wheels

For ID/OD Grinding

When a grinding application is simply too abrasive or demanding for standard resin bond wheels, Eagle Superabrasives has you covered with our MultiTEC line of metal bond diamond & CBN wheels. We utilize a proprietary titanium coating that is physically and chemically bonded to the abrasive particles contained within our metal bonds.

For the actual bonding process, we have added an additional processing step to the traditional three-step manufacturing process, resulting in the true amalgamation of the metal alloys and abrasive particles into one consistent, cohesive block. These advancements have launched Eagle’s MultiTEC wheels into the top spot in the market when it comes to wheel strength and durability.

These wheels can be designed, manufactured and shipped within four weeks and are backed with Eagle’s titanium-clad performance guarantee.

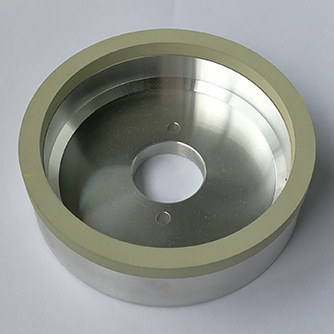

VitTEC Wheels

Eagle’s proprietary VitTEC diamond and CBN wheels are made for operators looking for more out of their vitrified grinding wheels.

What sets our VitTEC wheels apart from other vitrified diamond & CBN wheels is Cold Isostatic Pressing (CIP). While ordinary vitrified wheels are only pressed from two dimensions, ours are evenly pressed from every single side, angle, and radii during the CIP process.This guarantees that our wheel segments have perfectly consistent density throughout the abrasive section.

Pro-Grind Wheels

Eagle Superabrasives developed our Pro-Grind System with an eye toward setting ourselves apart from typical centerless grinding wheels. With multiple bonds, core types and grit sizes available, Pro-Grind centerless and regulating wheels provide you with mirror-like finishes and maximized throughput speed.

Our Pro-Grind wheels can be produced to your specifications in as little as three weeks.