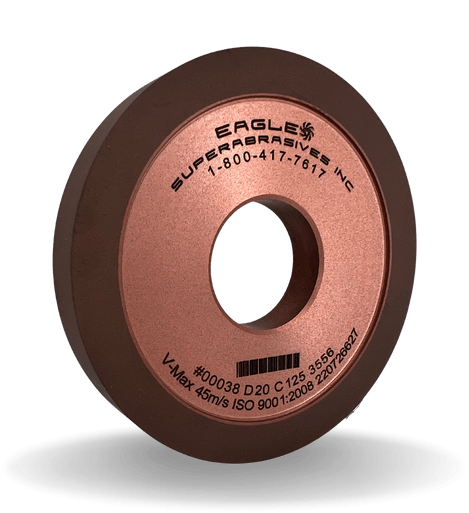

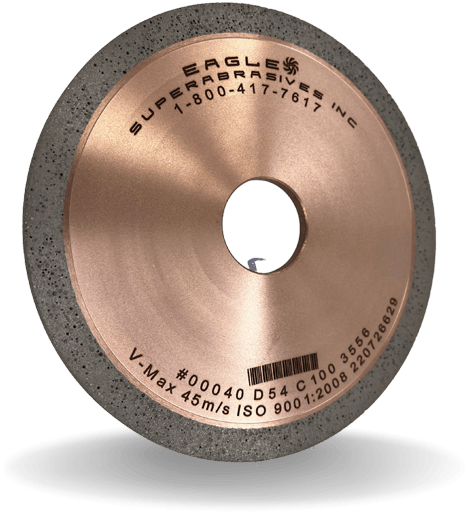

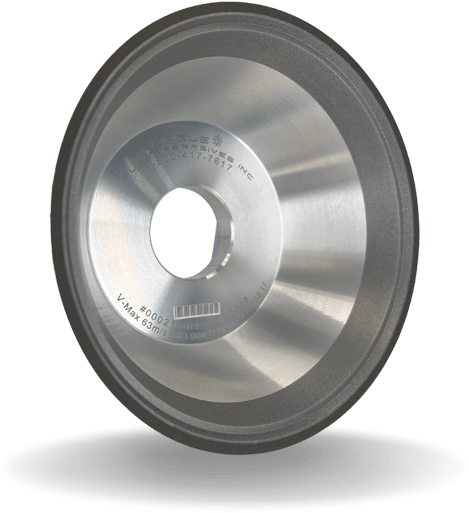

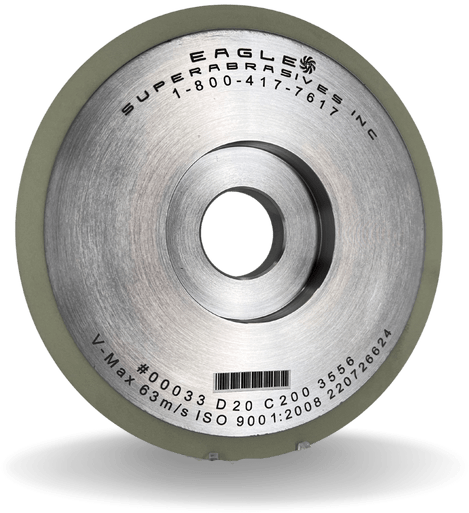

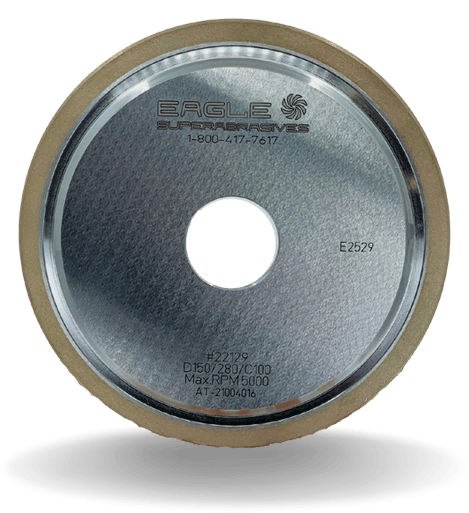

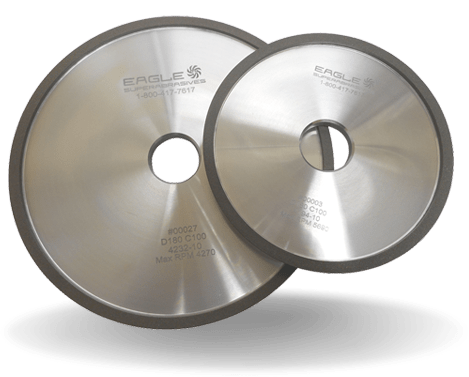

BONDED GRINDING WHEELS

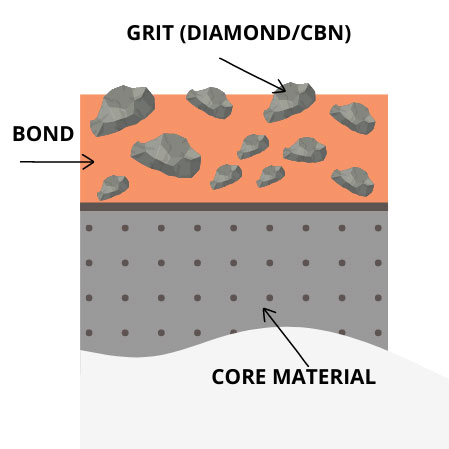

Superabrasive bond technology is constantly evolving with the availability of superior resins with improved heat tolerance, better fillers to combat burning, add lubricity and porosity combine to make different types of grinding wheel bonds cut cooler.

Today’s diamond / CBN bonds improve cutting action by providing the right amount of support for the abrasive material. Additives are mixed into the bond and the diamond or CBN is coated, reducing diamond pull out and therefore increasing bonded grinding wheels life and efficiency.

THE IMPORTANCE OF THE TYPES OF BONDS IN GRINDING WHEELS

The bond of a diamond/CBN wheel is one of the most important factors when choosing the correct wheel for the job. Our unique bond system retains the abrasive particle longer than most other bond systems, providing a longer wheel life and excellent wheel durability all while reducing heat build-up. We offer a variety of bonds for our diamond and CBN grinding wheels including Phenolic Resin, Polyimide Resin, metal bond, vitrified bond, and hybrid bonds – all of which can be custom made to fit your needs.

If the bond is too hard or too soft, it will adversely affect the grinding process. The grinding wheel bond must wear at the correct rate and hold the abrasive particle in place. In some cases, the bond is also used to transfer heat away from the grinding area.

Core Offerings

Working with Eagle, you can expect to discuss your project with one of our highly-skilled, U.S.-based application engineers. Together, they will help identify and provide the grinding solution that best fits your unique needs and goals. Our manufacturing capabilities are second-to-none in the industry.