Slicing Dicing & Wafering

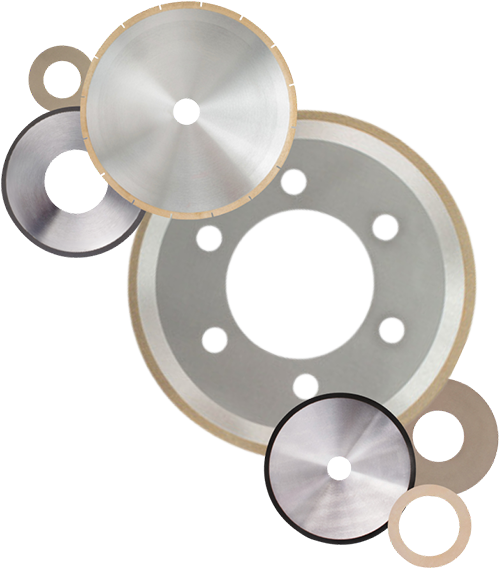

Eagle’s Precision Slicing & Dicing Blades

Here at Eagle, our large selection of high-precision slicing and dicing blades accommodate a wide range of needs, including:

- Semiconductor Slicing

- Ceramic Oxide Grooving

- Magnet Dicing

- Circuit Board Cutting

- difficult ferrous materials

- Carbide, Glass, Crystal & Quartz

- Tool steel, cast iron & stainless steel

- many more custom applications

Some blades are stock, but most are custom-made and optimized for your specific application. When you choose Eagle Superabrasives, you can expect precision kerfs and high quality cut finishes from a blade that’s made to last longer and deliver continuous, top notch results.

We have experience going into facilities, troubleshooting dicing applications, isolating machinery concerns and ramping up production. We know what it takes to get your blades operating at their optimum levels, and can assist in troubleshooting issues that might have plagued your production for years.

“We were having an issue with wheel breakage from our previous supplier, eagle came in and reviewed our process, suggested modifications to the coolant delivery and redesigned the wheel. We eliminated the breakage and increased performance by 5X – for the same price as we were previously paying” – Wes P

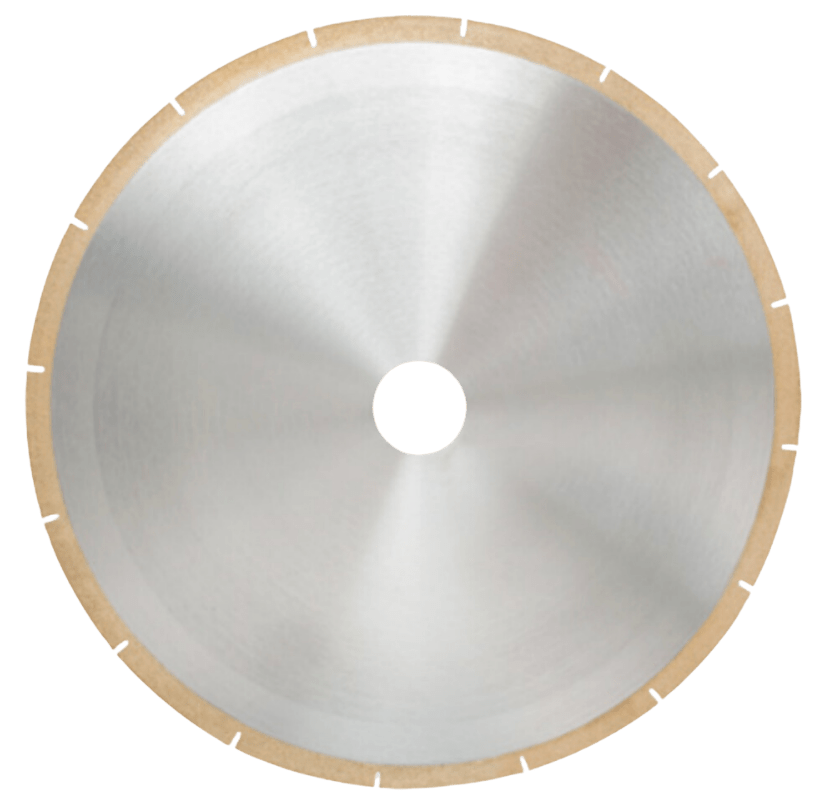

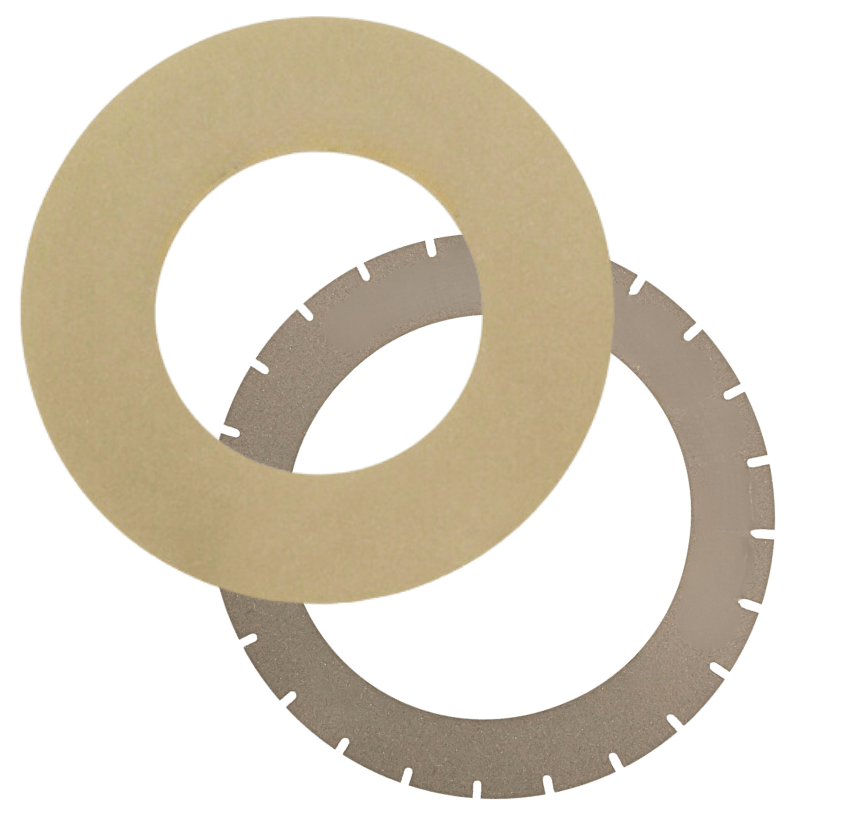

Resin Bond Diamond & CBN Blades

Resin bond dicing blades are hailed for their versatility, making them an indispensable tool in precision slicing and dicing applications. Their unique bond enhances self-sharpening capabilities, ensuring an impeccable surface finish with every cut. Their adaptability sets them apart by allowing for precise control over cutting efficiency, making resin bonded blades the preferred choice for industries demanding both precision and flexibility in their cutting processes. Eagle’s Resin Bonded Diamond Dicing Blades are available in multiple stock options, and fully customizable.

Resin Bond Blades Without a Steel Core

Resin bond blades without a steel core are ideal for precision cutting and slotting of various materials, from semiconductor components to carbide. These blades are used for a wide range of applications, and are the most cost effective option among industry standards. Eagle’s resin bond blades without the steel core are self dressing, and effectively balance high stock removal with high efficiency.

Applications

Resin bond diamond blades without a steel core provide high precision cuts on the most sensitive materials, reducing the likelihood of surface fracture. Common applications for resin bond diamond blades include:

- LGA

- Optical Glass

- Quartz/Gem

- Ceramics

- QFN

- DFN

- Carbide

- BGA

- Magnets

Features

- Wide Range of Versatility

- High Precision

- High Surface Quality

- Low Maintenance

- Cost Effective

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

Specifications

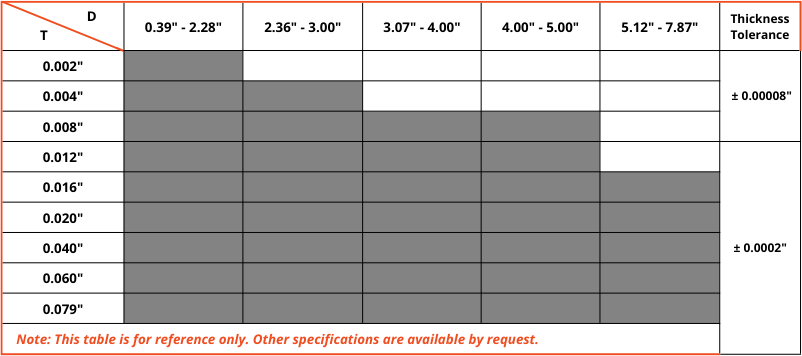

Reference Table of Thickness Tolerance by Wheel Size (Resin Bond)

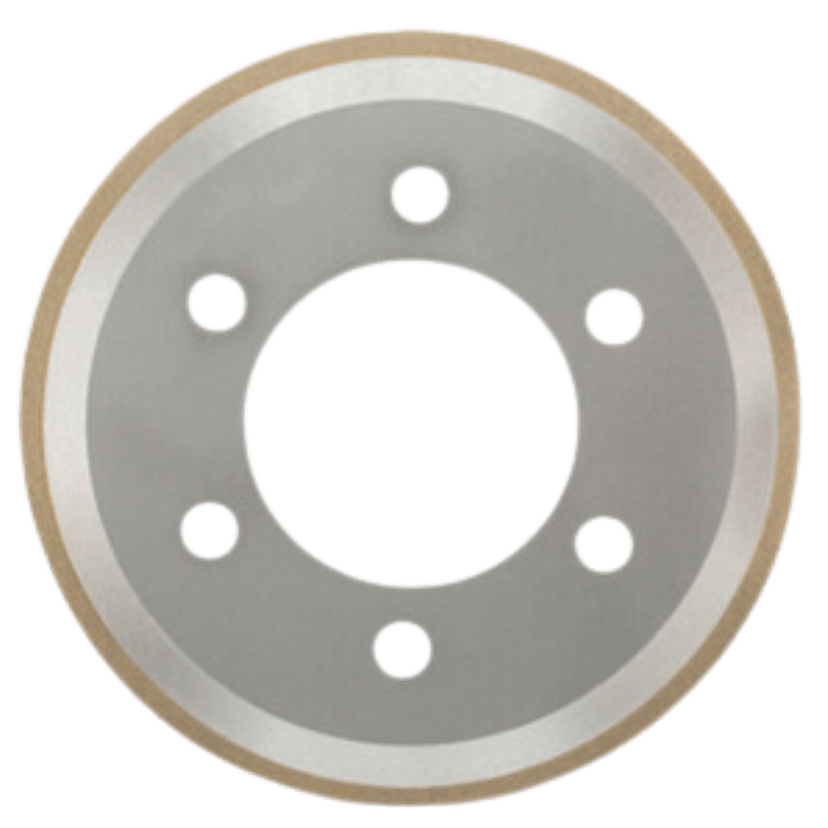

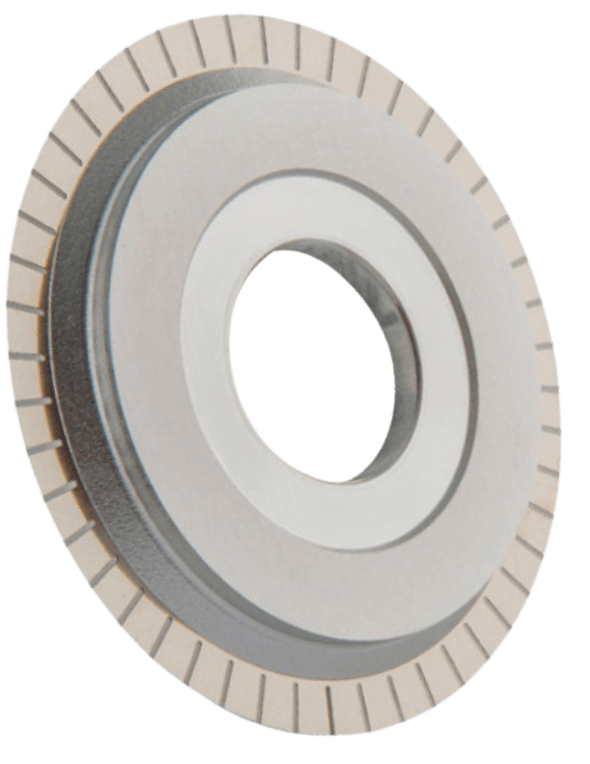

Resin Bond Blades With a Steel Core

Resin bond blades with a steel core provide outstanding accuracy and deliver high surface quality cuts. They are known best for being low maintenance and versatile, Eagle’s resin bond diamond blades with a steel core are available in a wide variety of shapes, and highly customizable to your exact needs.

Applications

Resin bonded CBN blades are typically used for the slotting and cutting of various steels and materials that are typically difficult to machine, such as:

- Tool Steel

- Bearing Steel

- Stainless Steel

- Crystal

- Carbide

- Magnetic Materials

- Ceramics

- Gems

- Mold Steel

- Heat Resistant Metalloids

- Cast Iron

- Quartz

Features

- Wide Range of Versatility

- Superior Cut Accuracy

- High Surface Quality

- Low Maintenance

- Cost Effective

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

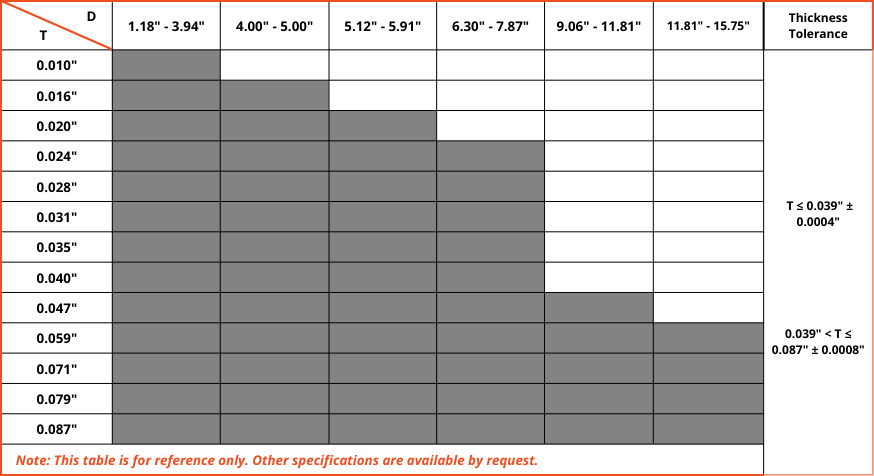

Specifications

Reference Table of Thickness Tolerance by Wheel Size (Resin Bond)

Metal Bond Diamond & CBN Blades

Metal bond diamond dicing blades are the ultimate in precision grinding and cutting. The excellent wear resistance provided by metal bonding agents allows them to hold form for extended periods before needing to be dressed. Metal bond dicing blades are available with or without a steel core. Blades without a steel core allow for high precision thickness tolerances, while the addition of a steel core provides high strength and rigidity to ensure maximum efficiency when performing deep cutting, grooving and slicing.

Metal Bond Blades Without a Steel Core

Metal bond diamond blades without a steel core are capable of providing incredibly high precision, as the removal of the core allows for the possiblity of a thinner blade. These blades are ideal for tight tolerance operations. Eagle’s metal bond blades offer the addition of an extended lifespan, ensuring your process performs at the highest level for as long as possible.

Applications

Metal bond diamond blades without a steel core are a popular choice for applications in precision cutting, including:

- Semiconductors

- (QFN, BGA, LGA, LED and Diode)

- Optical Glass

- (Filter, Blue Glass, Beveled Glass)

- Quartz, Crystal and Gems

- Magnetic Material

- Carbide

- Tool Steels

Features

- Tight Tolerance Sizing

- Ideal for Shallow Cutting

- Minimized Blade Wear

- Low Deflection

- Extended Lifespan

- High Precision

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

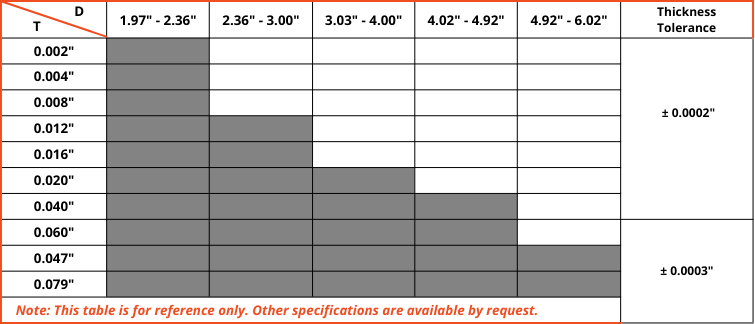

Specifications

Reference Table of Thickness Tolerance by Wheel Size (Metal Bond Without Steel Core)

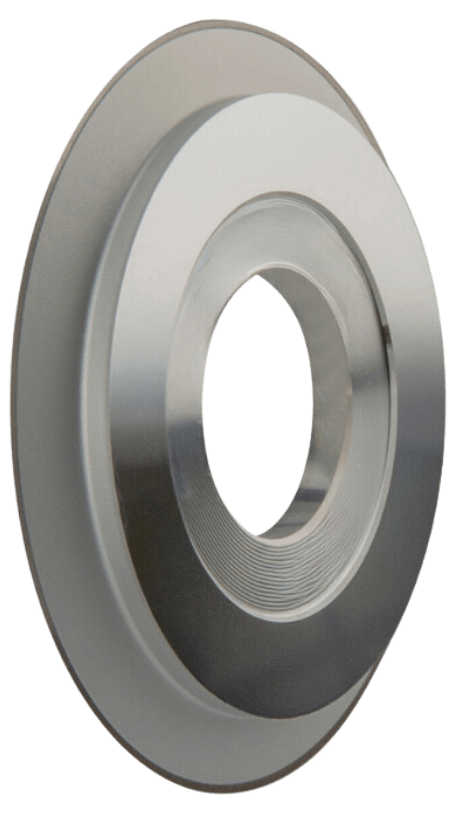

Metal Bond Blades With a Steel Core

Metal diamond bond blades with the addition of a steel core provide extra strength and rigidity to high precision operations. These blades are ideal for deep or aggressive cutting, grooving and slicing of both sensitive and durable materials. Eagle’s metal bond blades help ensure minimal deflection, preventing work piece damage and reducing your bottom line.

Applications

Metal bond diamond blades with a steel core are a popular choice for applications in high precision cutting that require a strong and rigid blade, including:

- Quartz

- Crystal

- Gemstones

- Optical Glass

- Glass Tubing

- Magnetic Material

- Ceramics

- Tool & Bearing Steels

Features

- Minimized Blade Wear

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

- Extended Lifespan

- High Rigidity & Precision

- Ideal for Deep Cutting, Grooving & Slicing

- Available with or without Water Slots

- Low Deflection

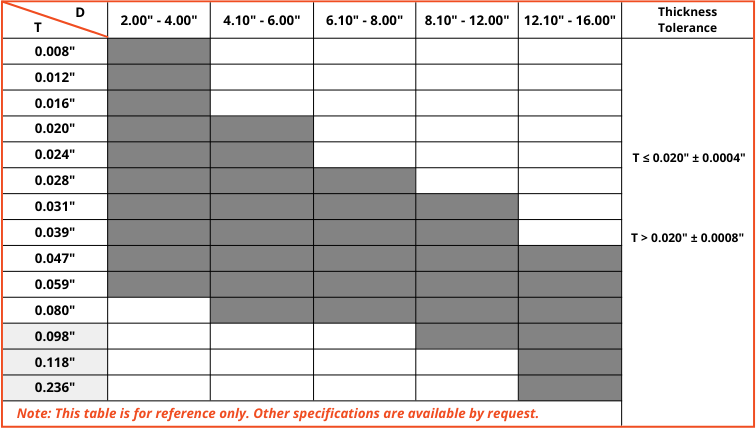

Specifications

Reference Table of Thickness Tolerance by Wheel Size (Metal Bond With Steel Core)

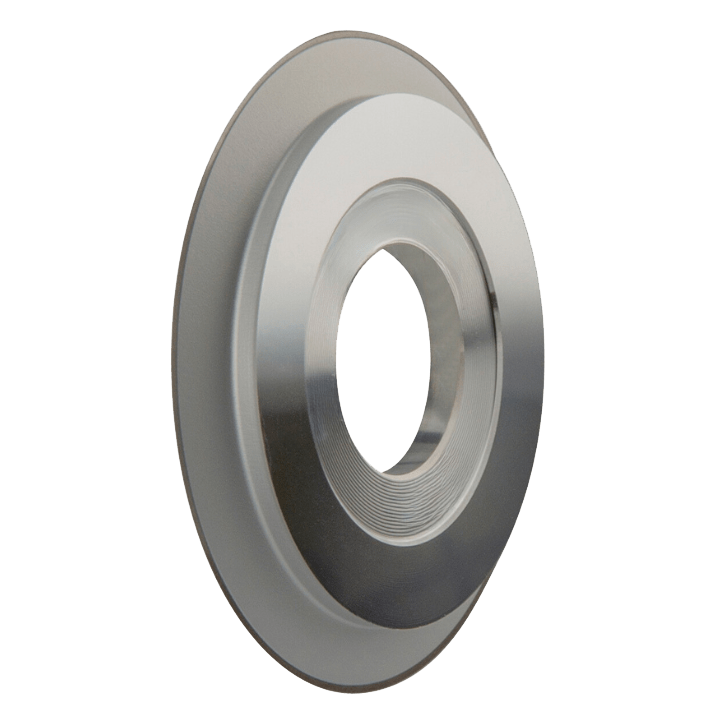

Electroplated/Nickel Bond Diamond & CBN Blades

Electroplated dicing diamond blades, also known as nickel dicing blades, are a popular choice for semiconductor component manufacturing. Ultra thin hub blades provide high stability, dicing narrow wafers with impeccable precision. Combining the electroplated bond with larger size diamond grit ensures an extended lifespan and consistent quality. Eagle’s EP/Nickel Bond Blades are highly customizable and available in a wide range of stocked variations, with or without a center hub.

EP/Nickel Bond Blades Without a Center Hub

Nickel bond diamond blades without a center hub are capable of providing incredibly high precision, available slotted or un-slotted. These blades are ideal for tight tolerance operations, thin slicing, and precision dicing applications. Eagle’s EP bond blades offer the addition of an extended lifespan, ensuring your process performs at the highest level for as long as possible.

Applications

Nickel bond diamond blades without a steel core are a popular choice for applications in precision cutting, including:

- Alumina Ceramics

- Oxide Wafers (LiTaO3, LiNbO3)

- Silicon Wafers

- EMC

- PCB

- GaAS

Features

- Tight Tolerance Sizing

- Ideal for Package Singulation

- Minimized Blade Wear

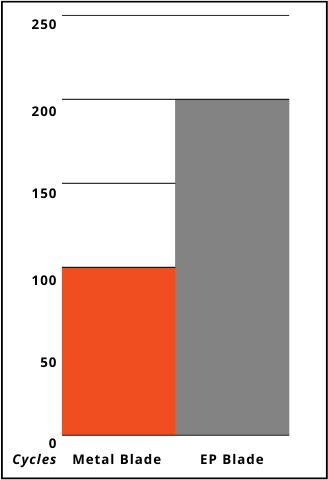

- Double the Lifespan of a Metal Bonded Blade

- High Precision

- Low Deflection

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

Specifications

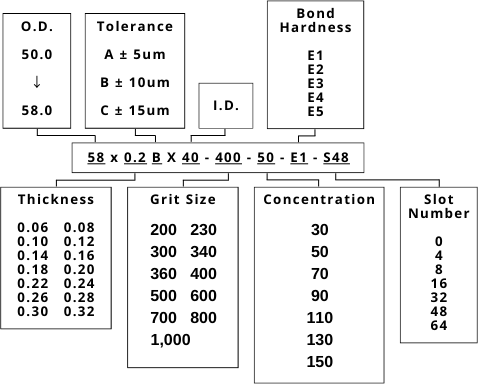

Part Number Detailed Reference Guide, EP Bond Blades without a Center Hub

Lifespan Comparison by Cycle of Metal vs Nickel Bond Blades

EP/Nickel Bond Blades With a Center Hub

Nickel bond diamond blades with the addition of a center hub provide exceptional stability, a necessary feature when dicing narrow wafers. These blades are ideal for tight tolerance operation and precision dicing applications. Eagle’s EP bond blades offer the addition of an extended lifespan, ensuring your process performs at the highest level for as long as possible.

Applications

Nickel bond diamond blades with a hub are a popular choice for applications in precision dicing, including:

- Oxide Wafers (LiTaO3)

- Silicon Wafers

- Compound Semiconductor Wafers (GaAP, GaA, etc.)

Features

- Tight Tolerance Sizing

- Ideal for Wafer Dicing

- Minimized Blade Wear

- High Precision

- Low Deflection

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

Specifications

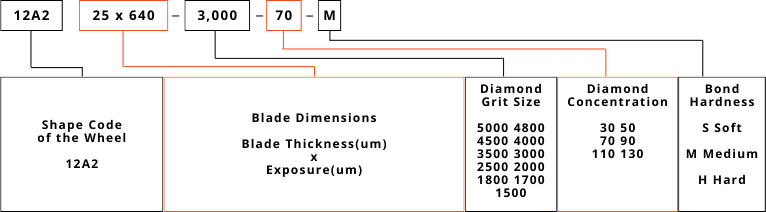

Part Number Detailed Reference Guide, EP Bond Blades without a Center Hub

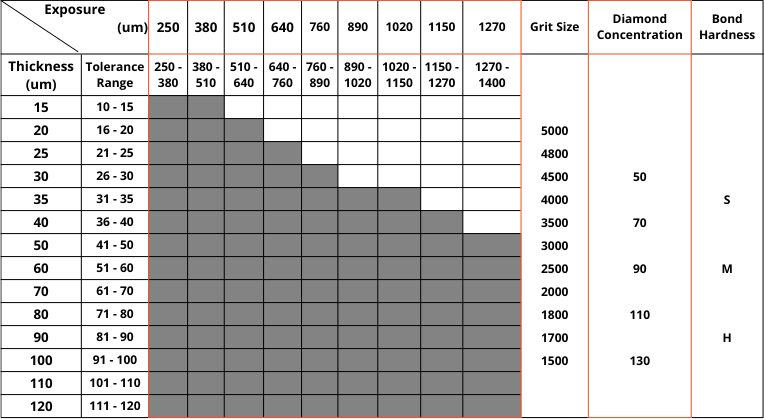

Reference Table of Thickness Tolerance by Exposure (EP Bond with a Center Hub)

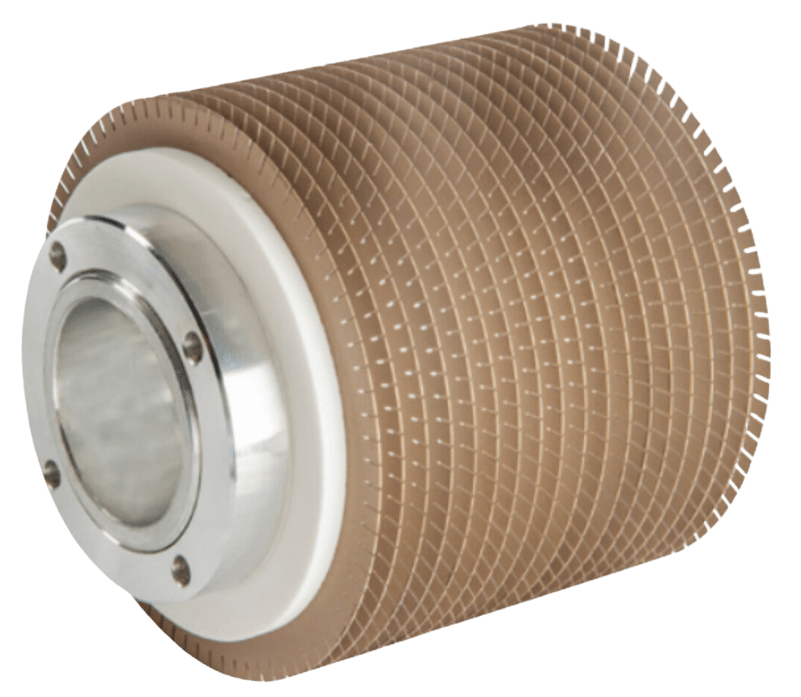

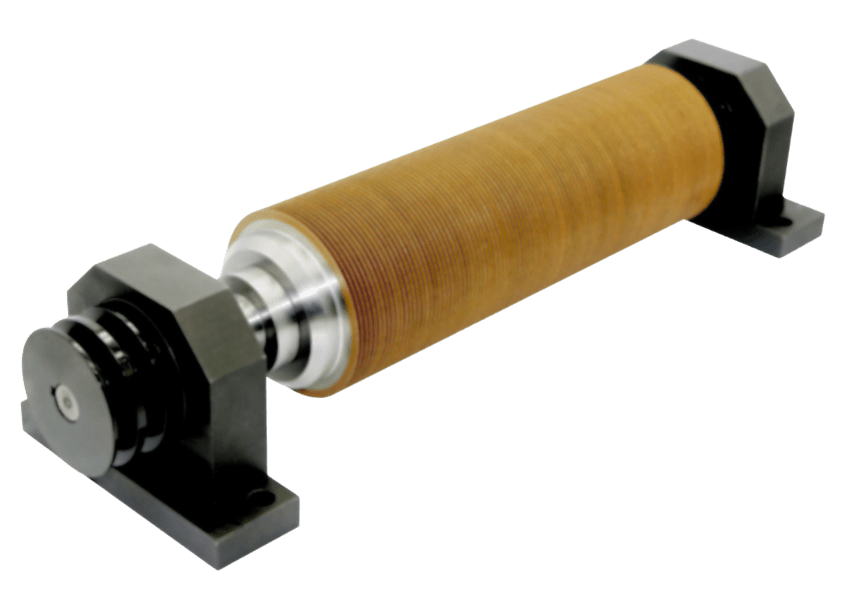

Back Grinding Wheels

Back Grinding Wheels are commonly used in semiconductor and LED manufacturing for the process of thinning various types of wafers. Back grinding wheels are ideal for flat grinding and chamfering polycrystaline silicon, as well as flat and cylindrical grinding monocrystaline silicon. These wheels provide uniform material removal for tight tolerance operations, all while improving the surface finish. Eagle’s highly efficient back grinding wheels are available in a wide range of stock shapes and sizes, and are highly customizable to your specifications.

Applications

Back grinding wheels are a popular choice for applications in wafer thinning, such as:

- Carborundum Wafers

- Integrated Chips (IC)

- Polycrystaline Silicon

- Monocrystaline Silicon

- Silicon Wafers

- Sapphire Wafers

- GaAS & GaAN Wafers

Features

- Tight Tolerance Grinding

- Superior Thermal Management

- High Efficiency Stock Removal

- Extended Lifespan

- Provides Desired Surface Finish

- Available in Diamond, CBN, and Custom Grit Formulas

- Highly Customizable Sizing/Shape

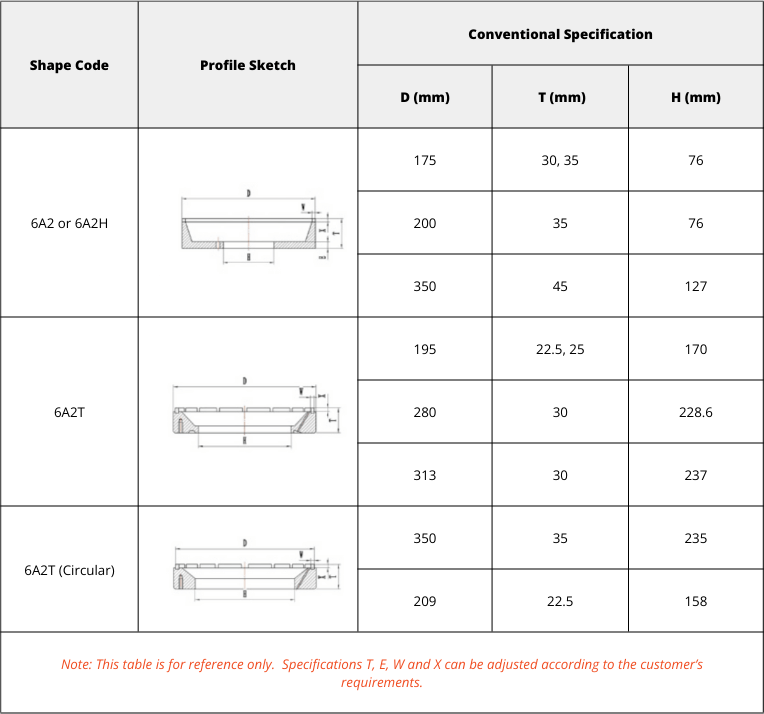

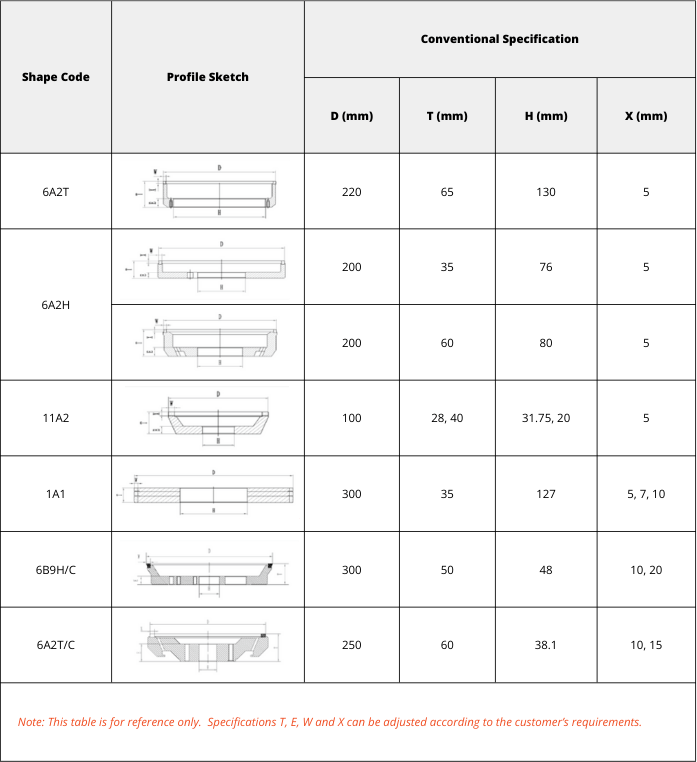

Specifications

Back Grinding Wheel Shape Code Detailed Specification (1/2)

Back Grinding Wheel Shape Code Detailed Specification (2/2)

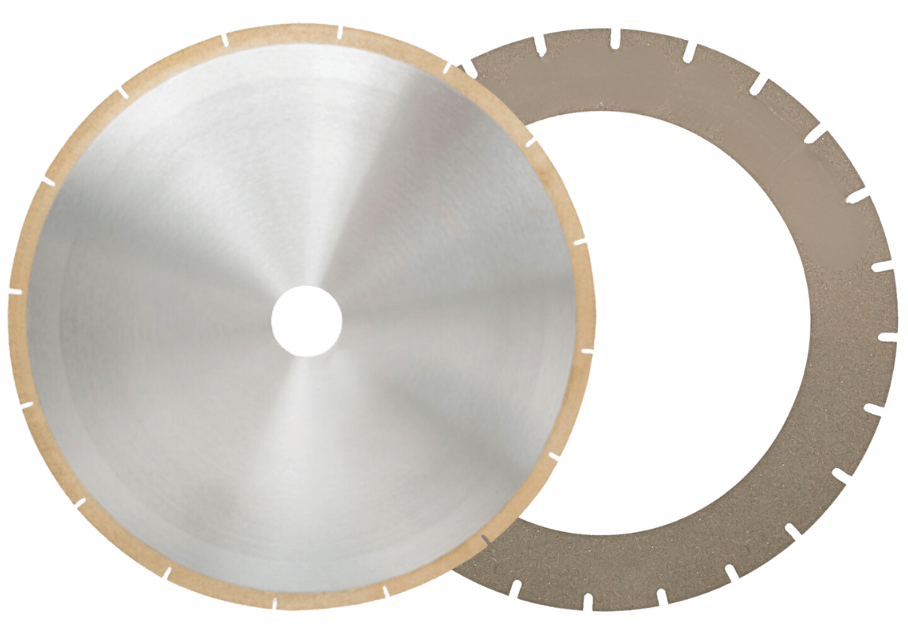

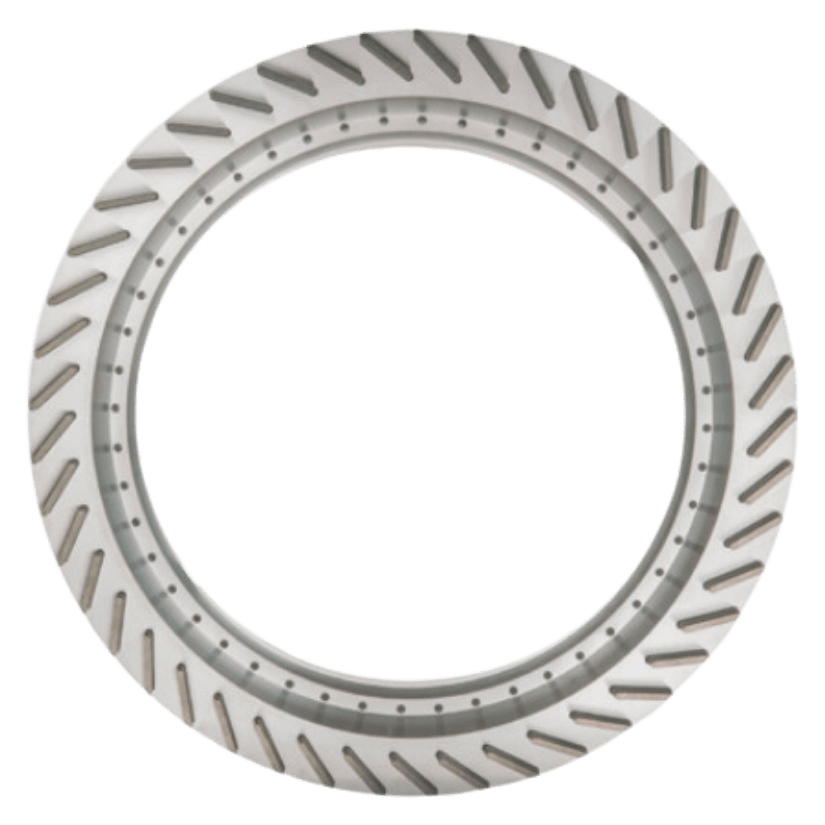

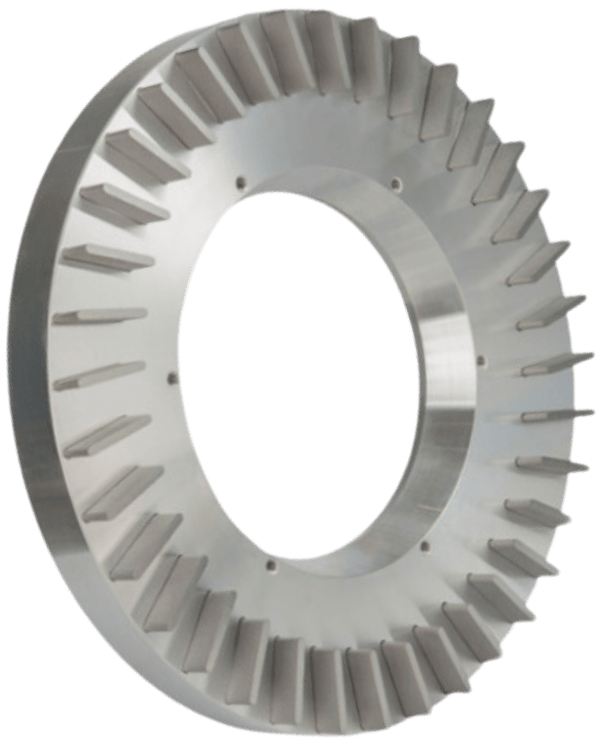

Gang Saw Dicing Blades

Gang Saw Blades are manufactured to extremely high tolerances. These blades are available with or without steel cores and in a wide variety of shapes and sizes. Eagle’s diamond dicing saw blades are fully customizable, from the addition of serrations to grit formula.

Applications

Diamond dicing saw blades are mainly used for dicing difficult-to-machine materials, such as:

- Optical Glass

- Electric Components

- Glass Tubing

- Quartz

- Gems

- Magnetic Materials

- Ceramic Pipes

- Tool & Bearing Steels

- Carbide

Features

- Highly Customizable Sizing, Shape and Grit Formula

- Available in Resin Bond, Metal Bond & EP Bond

- Manufactured to Tight Tolerances

- Provides Repeatable & Consistent Results

- High Efficiency

- Waste Reducing

Worried that a stock wheel won’t cut it for your application?

No worries! We manufacture custom wheels daily, and some of these wheels can ship in as little as seven days.

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898