Centerless

Centerless Grinding Wheels

Eagle Superabrasives has your centerless grinding wheel needs covered. Our product has been proven in the largest and most demanding grind shops in the industry. We produce wheels designed to provide the ultimate in material removal rates, wheel life and a perfect mirror-like finish.

Each wheel is custom made to your needs with our six unique bonds and a choice of Billet, Aluminum, Composite and Ceramic cores. Our PRO-GRIND wheels are produced using high quality CNC machinery. They are made of rigorously inspected raw materials ensuring maximum repeatability. To guarantee our products satisfy your grinding needs, we follow up with a 22-step quality control inspection program.

Specifications available for infeed, end-feed & through-feed applications!

Machine Types

- Koyo

- Churchill

- Ghiringhelli

- Glebar

- Royal Master

- Cincinnati

- Lidkoping

- Estarta, etc.

Work Pieces

- Bars

- Tubes

- Fasteners

- Bearings

- Rotors

- Valves

- Balls

- Needles

- Medical Wires

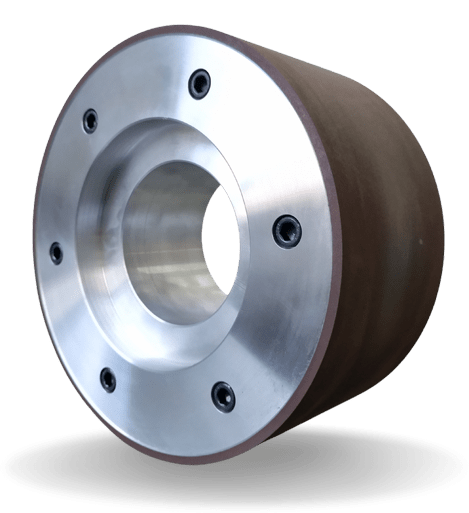

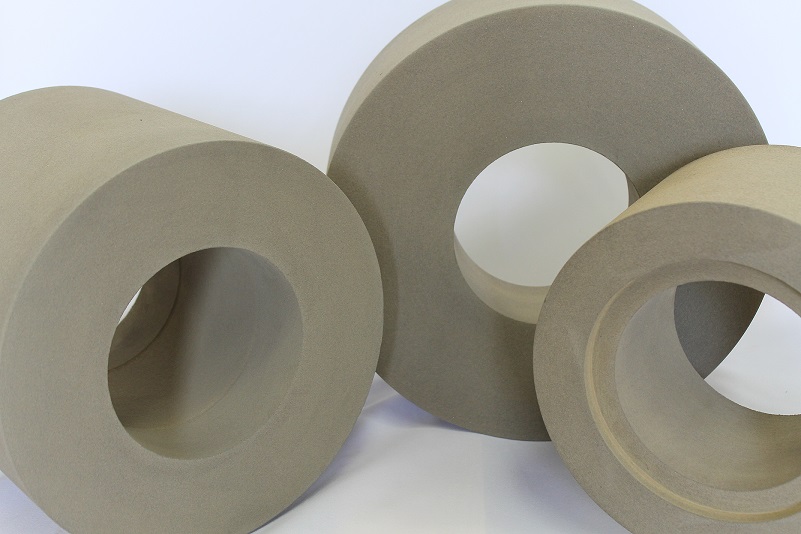

Regulating Wheels

Eagle’s HyperGrip Rubber Matrix Technology delivers the ultimate holding power. Our regulating wheels are manufactured to the highest tolerances using a 100% natural rubber bond matrix. The matrix holds the abrasive grain in place and provides consistent abrasive exposure. These wheels provide excellent grip allowing for high stock removal and a consistent rotation of the workpiece.

Rubber Bonded Regulating Wheels (also called Control or Feed Wheels) are manufactured by the rubber calendaring process for optimum performance.

Pro-grind System

Unlike typical centerless wheels, the Eagle Pro-Grind System incorporates a series of industry-leading formulations with multiple bond, core and grit size options. This system provides consistent mirror-like finishes and exceptional material removal rates while maximizing throughput speed. Our Pro-Grind wheels can also be made in as little as three weeks and ship to you freight free to keep your production line running at peak efficiency.

Pro-Grind Offers Solutions

Truing and dressing wheels.

Pro-Grind wheels are supplied mounted and balanced to your wheel adaptor ensuring you a perfectly true and smooth running wheel right out of the box.

Only one choice of core material.

Pro-Grind wheels can be made on one of four core materials.

Lack of customization.

Pro-Grind wheels come with six bond options.

Limited grit sizes available.

Pro-Grind wheels are made in grit sizes from 60 Mesh to 4 Micron

8-12 week delivery.

Pro-Grind wheels can be made in as little as three weeks.

Poor choice of regulating wheels.

We can supply high-quality regulating wheels.

High freight costs.

All Pro-Grind wheels ship to you freight free!

Worried that a stock wheel won’t cut it for your application? No worries! We manufacture custom wheels daily, and some of these wheels can ship in as little as seven days.

An Industry Leader

With Decades of Experience

Why Buy

From Eagle?

Trust the Experts

When you’re ready to try the best, trust the experts at Eagle Superabrasives. We offer unparalleled customer support and service.

With an extensive inventory of over 6,000 diamond, CBN and CDX wheels in stock at our North Carolina location, we are capable of shipping 90% of orders same day. Custom orders can be shipped in as little as seven days.

Our experienced staff is dedicated to providing our customers with high-quality products and excellent service. We offer technical support and advice to assist you along the way.

your grinding wheel needs.

When you’re ready, contact us for a free quote

or call us at (828) 759-5898